|

Jiangyin Reliance International Trade Company

|

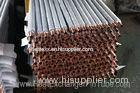

B111 Cooper & Copper-Alloy Tubes , Solid Extruded Bimetallic Condenser Fin Stock

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

B111 Cooper & Copper-Alloy Tubes , Solid Extruded Bimetallic Condenser Fin Stock

<span style="color:r

B111 Cooper & Copper-Alloy Tubes , Solid Extruded Bimetallic Condenser Fin Stock

ASTM B111/ B111M : Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stock

Quick Detail:

| General extrusion production capacity | General specifications of DR Type-Extruded Fin Tubes |

|

Extrusion Facility: 10 finning machines. Daily capacity up to 3000 meters. Extruded fins type: solid and serrated.

|

Tube OD: 50.8mm(2'') max. Tube Length: 18 meters max. Fin Height: 16.5 mm max. Fin Thickness: appr. 0.4mm Fin Pitch: 1.5mm min. |

Description:

Manufacturing Process

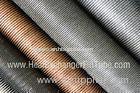

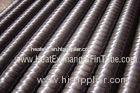

A smooth core tube is inserted into an aluminum sleeve and then the fins are extruded out of the aluminum sleeve.

Fins Type:

The fins are solid plain or serrated into 12,16 or 24 segments or as your design.

Unfinned Section

Both plain ends with appr. 10mm~50mm and gaps (Unfinned Section) in the middle.

Surface Coating

Both bare ends of Bimetallic Finned Tubes shall be Zinc or Aluminum that metallized applied by an electro spray arc system coating.

Accessories

Tube Support Box, Clamp or Spacer Box(Materials: Aluminum, Zinc or Stainless Steel).

Applications:

The common application fileds are:

- Heat exchangers units for power plant(electric, nuclear, thermal and geothermal power plants);

- High corrosive systems (condensers, evaporators, sea water desalinations, fertilizing, urea systems, ammonia, gas, corrosive acids);

- The petroleum, chemical and petrochemical industries;

- The food processing and refrigeration industries;

- Natural gas treatment;

Specifications:

Solid Extruded Bimetallic Finned Tube is combined with two different materials.

| Items | General Materials | Popular ASTM Materials |

| Core Tube Material |

Any metallic materials, as carbon steel, low-alloy steel, stainless steel, brass, copper, cooper-nickel alloys, aluminum bronze, nickel alloys et. (Core tube with extremely thin wall materials can be applied.) |

1. Carbon Steel: A179, A192,SA210 Gr A1/C,A106 Gr B 2. Stainless Steel: TP304/304L,TP316/TP316L/316Ti, A789 S31803/S2205 etc... 3. Copper:UNS12200/UNS14200/UNS70600, CuNi70/30,CuNi 90/10 4. Titanium: B338 Gr 2 |

| Fins Material |

1. Aluminum 2. Copper. |

1. Aluminum(Alu.1100,Alu.1060,Alu.6063) 2. Copper. |

|

All dimensions are in Inches and specification upon your requests. |

|||

|

Tube OD |

Fin Height |

Fin Thickness |

Fins per Pitch(Density) |

|

5/8 |

3/8,1/2 |

.015/.016/ .020 |

4, 5, 6, 7, 8, 9, 10, 11, 12 |

|

3/4 |

3/8,1/2,5/8 |

.015/.016/ .020 |

4, 5, 6, 7, 8, 9, 10, 11, 12 |

|

1 |

3/8,1/2,5/8 |

.015/.016/ .020 |

4, 5, 6, 7, 8, 9, 10, 11 |

|

1 1/4 |

3/8,1/2,5/8 |

.015/.016/ .020 |

4, 5, 6, 7, 8, 9, 10, |

|

1 1/2 |

3/8,1/2,5/8 |

.015/.016/ .020 |

4, 5, 6, 7, 8, 9, 10, 11 |

|

1 3/4 |

3/8,1/2,5/8 |

.015/.016/ .020 |

4, 5, 6, 7, 8, 9, 10 |

|

2 |

3/8,1/2,5/8 |

.015/.016/ .020 |

4, 5, 6, 7, 8, 9, 10 |

|

Please email us for more information. |

|||

Competitive Advantage:

- We have more than 10,000 square meters workshop, including 10 extrusion finning machines, daily extrusion capacity up to 3,000 Meters.

- The extrusion finning machines are designed and assembled by ourselves and we can offer you finning machines, extrusion muff sleeves and all accessories (extrusion finning disks) etc...

- DR-extruded bimetallic fin tubes maximum operating temperature: 300 degree. The transfer coefficient remains steady.

- DR-extruded bimetallic fin tubes have stronger fins than other mechanical fins, like L, LL, KL, and G, so it is much easier to clean.

- In application of high stress and corrosive condiction, DR-extruded bimetallic